When healthcare facilities face unstable electricity supply, one of the biggest risks is vaccine spoilage.

Rural health facilities often face the same responsibility as large urban hospitals — to store vaccines safely and keep them potent until use.

Vaccine wastage is driven by temperature excursions, unexpected power outages, and operator errors.

For decades the Ice-lined passive storage device has been a backbone of vaccine storage in areas with intermittent power.

Views: 0 Author: Site Editor Publish Time: 2025-07-09 Origin: Site

When it comes to choosing a drying oven for laboratory or industrial use, features like temperature range, capacity, and control precision often receive the most attention. However, one key factor that directly affects drying performance—but is frequently overlooked—is the air circulation design. How air moves within the chamber plays a decisive role in ensuring uniform heat distribution, consistent moisture removal, and optimal drying quality. Without proper airflow, even the most advanced heating systems can lead to uneven results, wasted energy, or compromised samples.

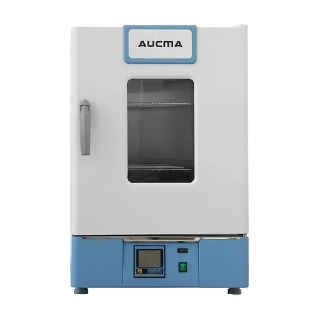

At Aucma, we recognize that air circulation is not just a support feature—it’s the core of high-performance drying. With over 35 years of expertise in precision thermal equipment, we’ve engineered our drying ovens with bottom-mounted fan-heater assemblies and precision-guided airflow paths, designed specifically to enhance thermal uniformity and protect delicate materials during processing. Whether you're working with pharmaceuticals, electronics, or chemical samples, the right air circulation system ensures faster drying, higher accuracy, and greater reliability.

Understanding how a drying oven works internally is essential to appreciating why air circulation plays such a pivotal role. A drying oven is more than just a heated box—it is a carefully controlled environment where temperature, airflow, and humidity interact to remove moisture effectively from various materials.

How Air Heats and Moves

When the oven is switched on, the heating elements begin to warm the internal air. In a forced-air convection drying oven, a circulation fan evenly distributes this hot air across all corners of the chamber. The air, now heated, makes contact with the items placed inside the oven, absorbing moisture and carrying it away as vapor.

Relationship Between Heat and Moisture Removal

The drying process is fundamentally a heat and mass transfer phenomenon. Heat helps evaporate moisture, but without a method to carry the vapor away, the moisture can recondense or linger, leading to uneven drying. Effective air movement helps reduce the boundary layer of moisture around the material, accelerating the drying process and ensuring consistency. Aucma ovens are designed to maintain a steady and controlled airflow throughout the chamber, resulting in superior drying outcomes for various applications such as curing, sterilization, and sample preparation.

Uniformity is critical in research, pharmaceuticals, and electronics—sectors where even minor inconsistencies can result in costly errors. Uneven airflow can cause fluctuations in internal temperature, directly affecting the reliability of the drying process.

Temperature Deviations

In poorly designed ovens, some areas may become hotter than others, creating thermal gradients. This inconsistency not only affects drying performance but also risks overheating sensitive materials. For instance, drying biological samples or precision-coated components requires a controlled environment to prevent degradation or structural damage.

Impact on Drying Consistency

Inconsistent airflow can lead to uneven moisture removal, causing parts of a sample to remain wet while others are overly dry. Such inconsistencies are unacceptable in quality-controlled environments. Aucma drying ovens are equipped with high-efficiency circulation fans and strategically placed heating elements that ensure hot air is evenly distributed, maintaining temperature uniformity within ±1°C across the chamber.

One of the unique technical highlights of Aucma’s drying ovens is the bottom-mounted configuration of fans and heaters, which plays a significant role in thermal stability and sample integrity.

Stability in Heating

Positioning both the heater and the fan at the bottom of the drying chamber allows for a stable upward airflow. This design takes advantage of natural convection tendencies while enhancing them with mechanical assistance. The result is an even heat distribution that starts from the bottom and reaches all corners of the chamber without abrupt temperature shifts.

Prevention of Sample Disturbance

Samples like fine powders or lightweight filters can be easily disturbed by strong or improperly directed air currents. Aucma’s bottom-up airflow minimizes turbulence near the sample surface. This design protects sensitive contents from being blown around, ensuring the integrity of the sample throughout the drying cycle. It’s especially beneficial in pharmaceutical, materials science, and analytical chemistry labs.

Many users overlook what happens after drying is completed. However, airflow still plays a role in the post-process stage, particularly for delicate or powdered samples.

Avoiding Particle Scattering

Continuing to run the circulation fan after drying may cause fine particles to become airborne, leading to contamination or loss. Aucma ovens feature the ability to turn off the fan once the desired temperature is reached, offering a calm and stable environment that prevents disruption of delicate samples.

Reducing Energy Consumption

In addition to preserving sample integrity, turning off the fan at the right time contributes to energy efficiency. By halting active airflow once the system reaches thermal balance, the oven reduces power usage without compromising the thermal environment. This not only extends equipment lifespan but also lowers operational costs—an important consideration for high-throughput labs and industrial facilities.

Time is often of the essence in both research and production environments. A drying oven that can achieve reliable and efficient results within a shorter time frame can dramatically improve workflow efficiency.

Faster Drying with Better Circulation

Efficient air movement enhances the evaporation rate by removing moist air quickly and replacing it with drier, heated air. This reduces the drying time significantly. Aucma’s ovens are engineered to deliver consistent airflow velocity across all shelves, ensuring that every item dries uniformly and swiftly, regardless of its position within the chamber.

Avoiding Hot/Cold Zones

Poor circulation creates zones that are hotter or colder than others. These inconsistencies lead to unpredictable drying patterns. With optimized fan and duct placement, Aucma ovens eliminate such zones, making them ideal for sensitive tasks such as drying electronic components, pharmaceutical powders, or medical instruments.

A high-quality air circulation design is only effective if it’s properly maintained. Preventive care and smart usage practices can significantly extend your oven’s service life and maintain peak performance.

Cleaning Side Plates and Fan Systems

Dust buildup, spilled materials, or particle accumulation can restrict airflow, decreasing efficiency and risking contamination. Aucma’s drying ovens are built with removable side wind plates and heating covers, allowing users to clean and inspect critical components easily. The stainless steel interior with rounded corners also simplifies daily cleaning.

Avoiding Overloading

Overloading is a common mistake that hinders airflow and causes uneven drying. It's crucial to leave adequate space between items to allow proper air movement. Aucma provides guidance on optimal loading practices to help users maximize productivity while maintaining consistent results.

Air circulation is not just a secondary consideration—it is the foundation of effective drying. A thoughtfully engineered airflow system ensures temperature stability, minimizes energy usage, prevents sample damage, and enhances operational efficiency. These are not optional features; they are essential for achieving high-quality results.

At Aucma, we integrate our decades of engineering expertise into every drying oven we manufacture. From bottom-mounted fan-heater assemblies to intuitive fan control systems, we focus on the features that matter most in real-world applications.

Contact us today to learn more about our cutting-edge drying ovens and how they can elevate your laboratory or industrial operations.