When healthcare facilities face unstable electricity supply, one of the biggest risks is vaccine spoilage.

Rural health facilities often face the same responsibility as large urban hospitals — to store vaccines safely and keep them potent until use.

Vaccine wastage is driven by temperature excursions, unexpected power outages, and operator errors.

For decades the Ice-lined passive storage device has been a backbone of vaccine storage in areas with intermittent power.

Views: 0 Author: Site Editor Publish Time: 2025-07-03 Origin: Site

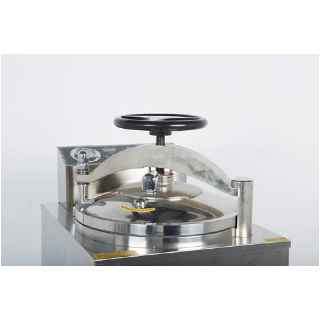

In environments where precision, cleanliness, and safety are non-negotiable—such as hospitals, clinics, and laboratories—the importance of effective sterilization cannot be overstated. Whether preparing surgical instruments or decontaminating biological waste, healthcare and scientific institutions depend on reliable equipment to maintain sterile conditions. One of the most trusted solutions in this regard is the autoclave for medical use. Thanks to its ability to destroy microorganisms, including heat-resistant spores, a high-quality autoclave is essential for infection control, regulatory compliance, and operational efficiency. Aucma’s advanced steam sterilizers meet the rigorous demands of medical and laboratory settings, offering dependable, user-friendly solutions to safeguard both patients and researchers.

Sterilization is the foundation of safe medical treatment and credible scientific research. Without thorough microbial control, both patients and experimental outcomes are put at risk.

In hospitals and clinics, sterilization directly protects patients from post-surgical infections, cross-contamination, and exposure to bloodborne pathogens. Instruments that are not properly sterilized can harbor dangerous bacteria, viruses, and fungi that compromise patient health and increase the burden on healthcare systems.

Similarly, in laboratory settings, contaminated instruments or glassware can skew data, invalidate experiments, and cause costly delays in research. For pharmaceutical labs or biosafety-level environments, improper sterilization can pose even broader public health threats.

Global health authorities such as the Centers for Disease Control and Prevention (CDC) and the World Health Organization (WHO) mandate rigorous sterilization protocols. Autoclaves are widely accepted as the gold standard due to their ability to reliably achieve sterilization benchmarks—typically 121°C at 15 psi for 15 to 30 minutes—ensuring compliance with these critical guidelines.

Aucma’s autoclaves are engineered with compliance in mind, meeting international standards such as ISO, CE, and national regulations, making them suitable for a wide variety of licensed medical and research environments.

Autoclaves use high-pressure saturated steam to kill microorganisms by denaturing proteins, disrupting cellular structures, and breaking down genetic material. This method is far more effective than dry heat or chemical sterilants, especially for complex or porous materials.

The combination of high temperature and pressure is the cornerstone of effective sterilization. Typical medical autoclaves operate at:

121°C to 134°C, depending on the type of material

15–30 psi of pressure, to drive steam into tight spaces

This environment kills even resilient bacterial spores that would otherwise survive under dry heat or chemical exposure.

One of the key advantages of steam is its ability to penetrate fabrics, rubber, and hollow instruments, making it ideal for sterilizing wrapped surgical packs, pipettes, tubing, and culture flasks. Aucma autoclaves are equipped with pre-vacuum and drying systems that ensure complete steam penetration and post-sterilization drying, minimizing the chance of microbial regrowth due to residual moisture.

Autoclaves in hospitals and labs are used to sterilize a wide range of tools, materials, and waste.

Surgical instruments such as scalpels, clamps, and forceps

Dressing packs and reusable linens

Glassware like beakers, petri dishes, and pipettes

Liquid media, including culture broths and reagents

Plastic and rubber items, when compatible with steam sterilization parameters

In addition, biohazardous waste, including infectious sharps, laboratory cultures, and contaminated disposables, can be safely sterilized prior to disposal. Aucma’s autoclaves offer adjustable settings to match these diverse sterilization needs, helping healthcare and laboratory staff stay productive and compliant.

Choosing an autoclave for medical or lab use isn’t just about size—it’s about functionality, safety, and integration into existing workflows.

Modern autoclaves should include pre-programmed and customizable cycles to accommodate:

Solid instruments

Liquids

Wrapped items

Biohazard waste

This flexibility ensures that every load is sterilized under the correct conditions, minimizing the risk of incomplete decontamination or material damage.

Aucma autoclaves are designed with multiple safety features to protect users, including:

Automatic pressure locks that prevent the chamber from opening under unsafe conditions

Temperature and pressure monitoring with real-time feedback

Emergency shut-off systems and fault alarms

Fast sterilization and integrated drying systems reduce cycle times, allowing medical and lab staff to stay on schedule without compromising on safety. Aucma’s intelligent PID control system ensures precise temperature and pressure regulation, while digital touchscreens simplify operation and reduce training time.

For laboratories, time and accuracy are paramount. Delays caused by outsourcing sterilization or redoing experiments due to contamination can derail progress.

With in-house autoclaves, researchers and technicians gain on-demand sterilization, eliminating dependency on centralized departments or external service providers. This autonomy translates into faster experimentation cycles and greater scheduling flexibility.

Sterile instruments and uncontaminated materials ensure that experiments yield reliable, reproducible results. This is especially important in biomedical and pharmaceutical research, where outcomes can influence clinical applications or regulatory approval.

Aucma autoclaves are built to support high-throughput environments, offering consistent sterilization across a variety of materials, backed by robust engineering and user-centered design.

In addition to infection control, autoclaves offer environmental and economic advantages that make them essential to modern healthcare management.

Many facilities opt for external sterilization services, but these can be costly, time-consuming, and logistically challenging. In contrast, in-house autoclaves:

Reduce recurring costs

Eliminate transportation delays

Offer greater control over cycle scheduling

This efficiency improves overall facility responsiveness and reduces administrative overhead.

Single-use items generate significant medical waste. By sterilizing reusable items with autoclaves, hospitals and labs can:

Lower their environmental footprint

Comply with sustainability mandates

Reduce purchasing costs over time

Aucma’s energy-efficient autoclaves also minimize power consumption without sacrificing performance, supporting both cost savings and environmental responsibility.

From operating rooms to biosafety labs, autoclaves have earned their place as the cornerstone of effective sterilization. Their ability to eliminate all forms of microbial life, handle diverse materials, and support fast, safe, and compliant operations makes them indispensable in medical and research environments. Aucma’s high-quality autoclaves are trusted by healthcare professionals and scientists worldwide, offering intelligent controls, advanced safety systems, and proven durability.

Contact us today to discover how Aucma’s autoclave solutions can enhance sterilization efficiency and safety in your facility.